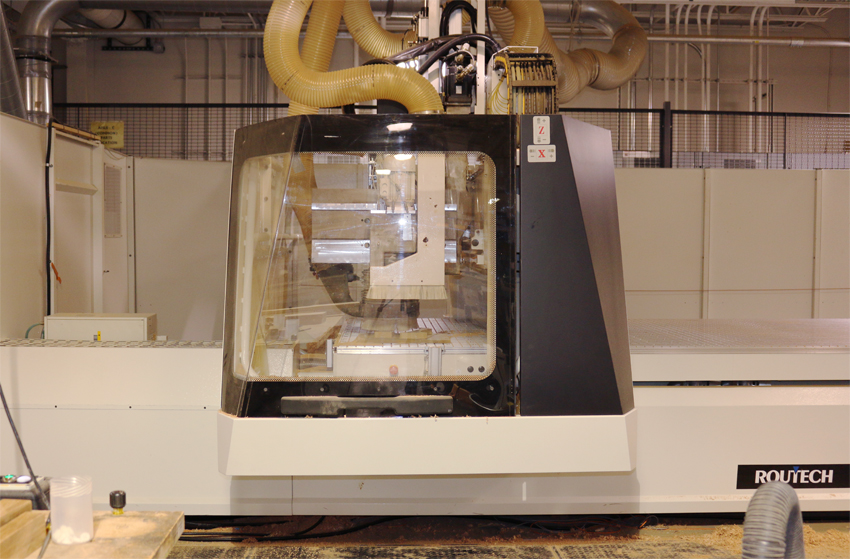

At Caretta Workspace, one of the most important pieces of machinery we use is our SCM Routech CNC Router. It's a computer controlled router that cuts along the X, Y, and Z axes. With a 15 horsepower spindle, it can easily tackle our 2.25" thick desk frames, and it has a 12 position automatic tool changer that can quickly switch from one cutter to the next. This allows it to easily cut a variety of profiles, like the bull-nose edge on our desktops, and transition into drilling holes for dowel pins or the inset for a desk inlay.

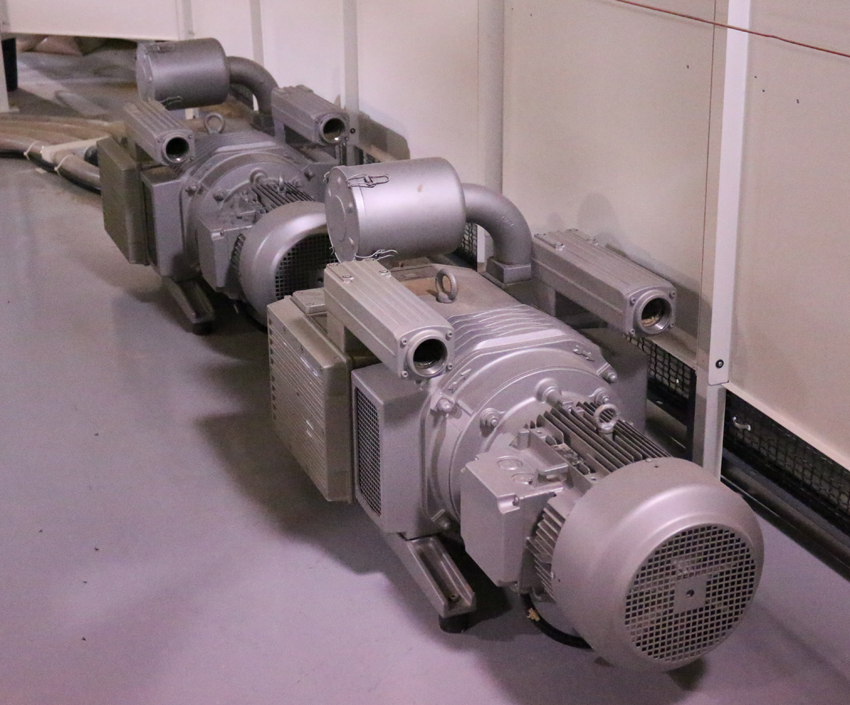

Eliminating the need for cumbersome clamps, the machine has two 12 horsepower vacuum pumps that create a suction to hold the pieces so firmly in place that they are impossible to move by hand. Although the pumps only produce about 10 psi of vacuum pressure, we design fixtures that maximize the surface area of the part being held. For example, a part that has 25 square inches of surface area to hold down has 250 pounds of force pushing it against the table. This allows us to make large cuts in the wood while the piece is held securely in place. The router is indispensable to our factory because it cuts our wood pieces much faster than we could cut them with traditional woodworking tools and it makes parts with such precision that each part fits perfectly together.

See the router in action here. At 1:40 is a good view of a tool change. At 3:10 you can see the LARGE bull-nose edge cutter in action. Here it is only cutting a half profile. On our large desk tops, it makes a full bull-nose edge.

This is a front view of the CNC Router in action.

Here are the Vacuum pumps that provide the negative air pressure to hold the parts to the table.

Here is the tool changer caddy.

In this Artistic Computer Desk 2, the router was used to make the desk top, desk legs, desk feet, and Artistic Computer Shelf.

No comments:

Post a Comment